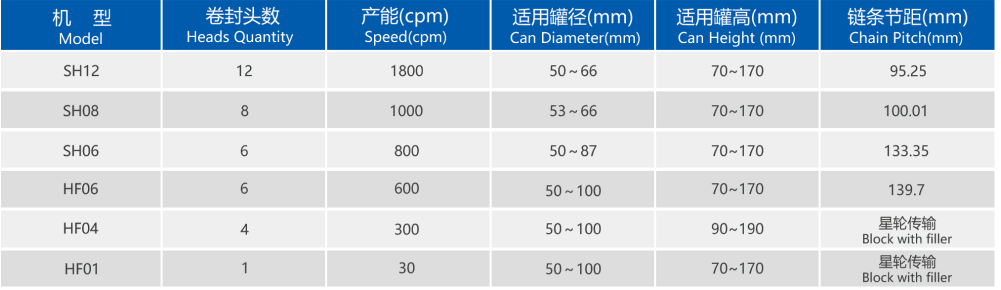

Can Seamer

Main Features

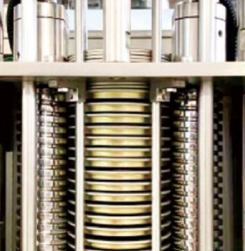

Applicable for multiple cans like aluminum, tinplate and plastic cans etc.

Applicable for normal, slim, sleek, stubby cans etc.

Stainless steel for visual parts & product contact parts.

Automatic closed loop lubrication for driving and seaming rolls,contribute to nonstop operation and low maintenance cost.

Modular design for quick changeover.

Motorized height adjustment.

CO2 / N2 / Steam flushing for under cover gassing.

Disengageable for 2nd seaming roll for accurate seaming parameters.

Servo or mechanical connection with filler.

Safety protection device.

Options

Auto Roll Lubrication

Lids Sterilization

Gas Flushing

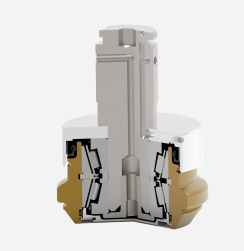

Seaming Parts